Quick Details

| Classification:Chemical Auxiliary Agent | Usage:Rubber Auxiliary Agents |

| CAS No.:102-77-2 | Brand Name:go chemical |

| Other Names:Accelerator MBS | Model Number:Industry |

| MF:C11H12N2S2O | Appearance:Light yellow or orange powder (granule) |

| EINECS No.:203-052-4 | Initial M. P, ≥:80℃ |

| Purity:98% Min | Loss on drying, ≤:0.3 |

| Place of Origin:Shanghai, China (Mainland) | Ash, ≤:0.3% |

| Type:Accelerators |

Supply Ability

- Supply Ability:

- 1000 Ton/Tons per Month Accelerator NOBS

Packaging & Delivery

- Packaging Details

- Accelerator NOBS: 25kg plastic woven bag, paper with plastic film bag, Kraft paper bag.

- Port

- Any main port in China

Product description

Accelerator NOBS (MBS)

Chemical Name:N-Oxydiethylene-2-benzothiazole sulfonamide

Classification: Accelerator

Molecular Formula: C11H12N2S2O

Molecular Weight:253.35

CAS NO:102-77-2

Specification:

| Item | powder | Granule |

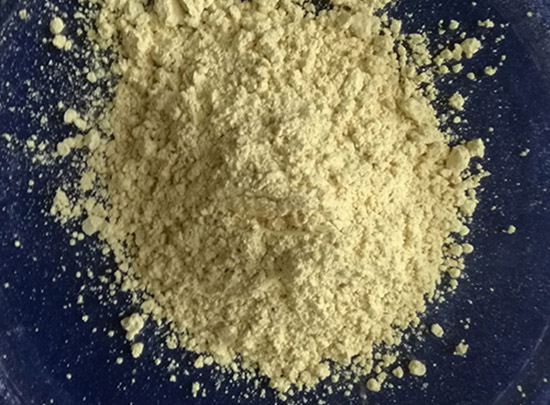

| Appearance | Light yellow or orange powder(granule) | |

| Initial M.P. ℃≥ | 80.0 | 80.0 |

| Loss on drying %≤ | 0.30 | 0.30 |

| Ash %≤ | 0.30 | 0.30 |

| Granule Diameter, mm | 1.50 |

Properties:

Light yellow or orange crystal (granule). No poison with a little odor of ammonia. The density is 1.34-1.40. Soluble in benzene, acetone. chloroform, insoluble in water, acid, and alkali with lower concentration.

Application:

An excellent delayed accelerator. The performance is similar as CZ with better scorch safety Widely used in NR, IR, SBR, NBR and EPDM. Can be used alone or with other vulcanization accelerators such as thiurams, guanidines and dithiocarbamates to improve the activity. Mainly used in manufacture of tires, shoes and belts.

Packaging:

25kg plastic woven bag, paper with plastic film bag, kraft paper bag or jumbo bag.

Storage:

The product should be stored in the dry and cooling place with good ventilation, avoiding exposure of the packaged product to direct sunlight. The validity is 1 year.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .